3.1. Compaction characteristics

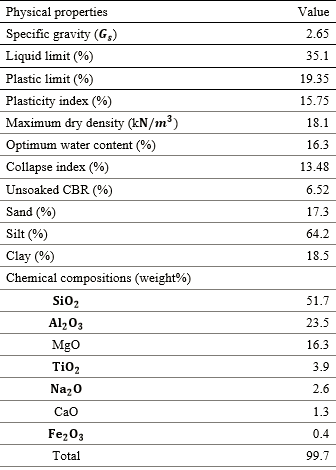

It is necessary to compact the soil after combining with biopolymers to a certain density level as part of the primary process utilized to improve soil layers. Other mechanical characteristics, including bearing capacity, settling, and shear strength, will be influenced by the achieved density after compaction. Therefore, the compaction characteristics of collapsible soil blended with various biopolymer contents had to be studied. When the biopolymer content of gelatin, xanthan gum, and sodium alginate increased, the maximum dry density\(\left({{\gamma }}_{\text{d} \text{m}\text{a}\text{x}}\right)\) decreased and optimum water content (OWC) increased, as shown in Fig. 2 and Fig. 3. For gelatin-treated specimens, when the concentration was increased from zero to 2%, the density dropped from 18.1 to 16.2 kN/\({\text{m}}^{3}\). The reduction in dry density was less for sodium alginate and xanthan gum than that for gelatin, where \({{\gamma }}_{\text{d} \text{m}\text{a}\text{x}}\) reached 17.94 kN/\({\text{m}}^{3}\) and 16.7 kN/\({\text{m}}^{3}\) at 2% sodium alginate and 2% xanthan gum, respectively.

This behavior can be explained by the soil partial weight and the biopolymer solution viscosity as the light weight of soil particles allows them to move away from one another in response to the influence of the solution viscosity, resulting in a total decrease in dry density. Furthermore, the solution viscosity increases when the biopolymer content increases, which results in an even further reduction in the dry density of the soil.

On the other hand, optimum water content rose from 16.30% at zero content to 21.40%, 18.12%, and 21.80% at 2% content of xanthan gum, sodium alginate, and gelatin, respectively. This behavior is because increasing the biopolymer content results in an increase in the absorbed water used to dissolve biopolymer, which matches the trend observed by (M. Ayeldeen et al., 2017; M. K. Ayeldeen et al., 2016; Chang, Prasidhi, et al., 2015; Dehghan et al., 2019).

3.2. Collapse index

The collapse index has been studied for two cases of dry densities according to the experimental program as shown in Table 2. For specimens prepared with a dry density of 1.36 kN/\({\text{m}}^{3}\), the collapse index was assessed for two cases of mixing techniques: dry mix and wet mix. The collapse behavior was considerably influenced by biopolymer type, biopolymer content, and mixing technique. As shown in Fig. 4.a, the collapse index was reduced by increasing xanthan gum content in dry and wet mix cases, but it was observed that the wet mix case was superior to the dry mix case. Figure 5 presents the impact of xanthan gum content on the collapse test results in the case of wet mixing. Even at low concentrations, the xanthan gum content has a considerable effect on the collapse index, as the collapse index was reduced from 13.48–7.14% by adding 0.50% xanthan gum content. When xanthan gum content increased to 1%, the collapse index decreased to 4.19%. The collapse index was reduced to 0.3%, which is approximately vanished, at a content of 4%.

Figure 6 presents the collapse index test results for untreated specimens and treated specimens with 4% xanthan gum for the two mixing methods. The collapse index was 13.48% for untreated soil, while it was 1.27% and 0.30% for dry mix and wet mix cases, respectively. The efficiency of xanthan gum was around 90% in decreasing the collapse index of the soil for the dry mix case, while it was 98% for the wet mix case.

The effect of sodium alginate and gelatin on the collapse index was similar to xanthan gum effect and it was obvious that the wet mix was more effective than the dry mix, as shown in Fig. 4.b and Fig. 4.c. Gelatin is less efficient than sodium alginate, and all of them are less efficient than xanthan gum, as presented in Table 3 and Fig. 7.

In the wet mix method, about 2.15% xanthan gum, 3.12% sodium alginate, and 4% gelatin are necessary to reach the "Slight" stage of the collapse index. For the dry mix case, about 2.9% xanthan gum content is necessary to reach the same stage, about 4% sodium alginate, and more than 4% of gelatin are needed.

According to (Chang, Im, et al., 2015), biopolymers’ specific surfaces are quite high and electrically charged, allowing for direct interaction with clayey soil particles. According to the microscopic behavior of the sample, which was stabilized by 2% xanthan gum, SEM pictures show a direct interaction between xanthan gum and soil particles, as shown in Fig. 15 which is presented in SEM results. The electrical charge of fine-grained soil particles may motivate this interaction, in which xanthan monomers are linked to the electrically charged soil particles via hydrogen bonding and cationic bonding between hydroxyl groups (-OH) and carboxylic acids (-COOH), which is accompanied by the aggregation of particles and filling the voids with air or biopolymer gel. The superiority of xanthan gum solution as compared with sodium alginate solution and gelatin solution is due to its stronger hydrogen bonding and smaller voids (M. Ayeldeen et al., 2017; M. K. Ayeldeen et al., 2016; Chen et al., 2013).

The similar effect was obtained for specimens which were prepared at a dry density of \(1.63 \text{k}\text{N}/{m}^{3}\)as shown in Table 4. With increasing biopolymer content, the collapse index was reduced. With a content of 4% of xanthan gum, sodium alginate, and gelatin, the collapse index decreased to 0.40%, 0.50% and 1.71%, respectively.

3.3. Shear strength

Shear strength is a key parameter of soil improvement. The shear strength parameters of the tested samples were obtained from the unconsolidated undrained triaxial test by plotting the stress Mohr’s circle and shear strength envelope diagrams as presented in Fig. 8. Figure 9, Fig. 10, and Fig. 11 present failure envelopes for untreated specimens and treated specimens with different contents of biopolymers. In comparison with untreated specimens, all treated specimens exhibited a considerable increase in cohesion intercept and total shear strength, although the friction angle was reduced. Figure 12.a shows that after mixing the soil with 0.5% of xanthan gum, sodium alginate, and gelatin, the friction angle has been reduced from 34.34° (for untreated sample) to 34.08°, 33.9°, and 34.2°, respectively. Increasing the content from 0.5 to 4% of xanthan gum, sodium alginate, and gelatin slightly reduced the friction angle to 31.66°, 31.312°, and 32°, respectively. This reduction is because the biopolymer coating effect on the surfaces of the grains softened the microscale roughness, resulting in less asperity interlocking of sand grains. This resulted in an inconsiderable decrease in the friction angle (M. Ayeldeen et al., 2017).

As shown in Fig. 12.b, cohesion intercept has been increased from 47 for zero content to 144, 117, and 95 kPa for 4% content of xanthan gum, sodium alginate, and gelatin, respectively. This improvement is because biopolymers have numerous chemical functional groups, like amines, ester, or hydroxyl groups, whose extended chains offer additional sites for the distinguished chemical interactions of a mentioned functional group to take place. Chemical bonding is responsible for the adhesive forces that hold the soil particles and the surface of the gel together (Khatami & O’Kelly, 2013). On a microscopic scale, the kinds of forces among the gel and the particles influence the efficiency of the bonding. Ionic/electrostatic or covalent connections (chemisorption), hydrogen bonding (strong polar attraction), and van der Waals forces (physical absorption) all operate at the interface between the gel and the particles. Short-range covalent and ionic/electrostatic bonds give the strongest bonds because of their high bond energy. Van der Waals forces give the weakest bonds over a long range. On the other hand, the increase in molecular weight of the biopolymer results in an increase in the solution viscosity because the higher molecular weight of the biopolymer enhances the opportunity of sustaining its macromolecule chain crystallization, which results in an increase in the degree of crosslinking within the soil matrix. Thus, the xanthan gum mixture had a higher shear strength than sodium alginate mixture and gelatin mixture because xanthan gum solution had a higher viscosity than sodium alginate and gelatin, as stated before in (M. Ayeldeen et al., 2017; Dehghan et al., 2019).

Cohesion stress isn't the only parameter influencing the soil shear strength. The increase in the biopolymer content led to a slight reduction in the friction angle and an increase in the cohesion stress. So, to study the shear strength behavior after soil treatment, the overall shear strength of the soil was determined in accordance with the next equation:

\({\tau }_{f}\) = c + (σ + γ h) tan ϕ

where \({\tau }_{f}\) is the soil shear strength which is presented in Fig. 12.c, c is the cohesion stress, σ is the external stress, ϕ is the friction angle, and γh is the overburden pressure at depth h of 1.50 m below the ground.

3.4. California bearing ratio

CBR is an important parameter for pavement design (Abo El-Naga et al., 2020). This depends on the fact that higher CBR offers a lower risk of strain under loads. Additionally, CBR is an expression of the shear strength, bearing capacity, and resilience modulus of the soil (Abo El-Naga et al., 2020; Choudhary & Joshi, 2014). Since this study is concerned in soil stabilization for construction purposes or to be used as subgrade for pavements, the engineering characteristic of interest is the CBR. Unsoaked CBR tests were performed on untreated specimens and treated specimens with biopolymer contents of 1%, 2%, and 3%. It is noticed that CBR was significantly increased by increasing the biopolymer content, as shown in Fig. 13 and Fig. 14. The findings also revealed that the xanthan gum effect on the CBR value was more remarkable than sodium alginate and gelatin. CBR increased from 6.52% (for natural soil) to 8.22%, 11.14%, and 16.14% when the soil was mixed with contents of 1%, 2%, and 3% of xanthan gum, respectively. The increase in CBR value was less in the case of sodium alginate and gelatin specimens, as shown in Fig. 13 and Fig. 14. The unsoaked CBR value increased by about 147%, 128%, and 117% when the soil was treated with concentrations of 3% xanthan gum, sodium alginate, and gelatin, respectively.

3.5. Discussion

The previous findings revealed that xanthan gum, sodium alginate, and gelatin can considerably alter both the chemical composition and physical structure of the collapsible soil. Biopolymers contain a large number of -COO- groups which become polyanionic when dissolved in water, causing adhesion. Biopolymer can form a hydrogel when it is combined with water under mild conditions (Ouwerx et al., 1998; Zhao et al., 2020). The soil's microstructure is considerably changed by this hydrogel. SEM study was performed on a sample of soil with 2% xanthan gum content. From the findings of SEM study shown in Fig. 15, it has been observed that xanthan gum has three main impacts on the soil's microstructure: First, the holes among the soil particles were filled by the colloids generated by xanthan gum, which resulted in reducing the soil's porosity. As a result, the contact among the particles altered from point contact to surface contact, which caused an increase in the contact area while the structure of the soil was strengthened. Second, addition of xanthan gum formed a coating effect on the particles, which were encapsulated by a film-like gel substance that increased the particle size. As the particles became larger, they could touch each other easier. Furthermore, because of flocculation, the clay particles remained bonded together and aggregated to form larger particles.

Also, the findings of XRD analysis have proved the coating presence for the used biopolymers. Figure 16, 17, and 18 indicate that there is no presence of new crystalline substance in the stabilized soil as the main minerals were still calcite and quartz. Although no additional peaks appeared, the intensities of the initial peaks in the XRD pictures gradually reduced as the biopolymer content increased, and the curve tended to be gentle, as shown in Fig. 16, Fig. 17, and Fig. 18. The SEM pictures indicated that this is because the biopolymer hydrogel enclosed the crystals. The hydrogel coating on the crystal surface blocked X-rays from being directed into the soil crystals, which is the same trend presented by (Zhao et al., 2020).