3. Experiments

3.1 Experimental Setup

Computer Numeric Control (CNC) machines are designed to machine complex components in various industries including heavy equipment, precision machines, automotive parts, aircraft, etc. A three-axis CNC engraving machine (DAVID 3020) manufactured by DAVID Motion Technology Inc. was used for the milling experiments as shown in figure 2 (a). Single 4mm thick Al plates were used in the experiments. The lower part of the plate was supported by a force sensor which has 60mm diameter and 18.5mm height and locked by the clamp at each corner as shown in figure 2 (b). The specifications of the machine are listed in table 4.

Table 4: Specification of DAVID-3200 CNC machine

|

Model |

DAVID-3020 |

|

X, Y, Z Workspace |

200 × 300 × 80 mm |

|

Table size |

450 × 240 × 15 mm |

|

Motor (X, Y, Z-axis) |

Precision STEP Motor |

|

Feed Rate |

50~3000 mm/min |

|

Positioning Repeat Accuracy |

≤ 0.03 mm |

|

Spindle |

800W (water cooling), 0~24000 rpm |

|

Power |

AC 220V |

|

Control |

G-code |

|

Software Compatibility |

TYPE3, MASTERCAM, ARTCAM, etc. |

3.2 Design of Experiment (DOE) based Taguchi method

To reduce the number of experiments, a fractional matrix of experiments was used. The spindle speed (rpm), feed rate (mm/min), Depth of Cut (mm), Endmill diameter (mm), and machining time (min) were chosen as controllable parameters affecting the surface roughness of the milled part. As listed in table 5, five factors at five levels were considered to ensure that all levels and all factors are considered equally and can be evaluated independently of each other[14].

Table 5: Factors and levels of Fractional factorial design for an experiment

|

Level |

Spindle Speed (rpm) |

Feed rate (mm/min) |

Depth of cut (mm) |

End-mill diameter (mm) |

Machining time (min) |

|

1 |

10000 |

5 |

0.2 |

1.0 |

1 |

|

2 |

12000 |

10 |

0.4 |

2.0 |

2 |

|

3 |

15000 |

15 |

0.6 |

3.0 |

3 |

|

4 |

20000 |

20 |

0.8 |

4.0 |

4 |

|

5 |

24000 |

25 |

1.0 |

5.0 |

5 |

The effects of machining parameters on the performance characteristics can be concisely examined using the Taguchi orthogonal array (OA) design of experiments (DOE). The DOE based on the orthogonal array can be used to estimate the main effects of an experiment using only a few experimental cases. L25 (55) Taguchi orthogonal array, containing the experimental parameters (viz., spindle speed, feed rate, depth of cut, end-mill diameter, and machining time) and their levels are shown in table 6. The parameter levels were selected for ease of comparison, and to find a correlation between the parameters and the surface roughness. New endmills were used for each Taguchi orthogonal matrix-based experiment.

Table 6: L25 (55) Taguchi orthogonal array used for the experiment, surface roughness values, and classes, and corresponding Vc and MRR

|

No. |

Spindle Speed (rpm) |

Feed Rate (mm/min) |

Depth of Cut (mm) |

End-mill Dia (mm) |

Operation Time (Min) |

Surface Roughness |

|

|

Value (Ra) |

Class |

||||||

|

1 |

10000 |

5 |

0.3 |

5 |

1 |

1.288 |

Smooth |

|

2 |

10000 |

10 |

0.6 |

4 |

2 |

1.949 |

Smooth |

|

3 |

10000 |

15 |

0.9 |

3 |

3 |

1.248 |

Smooth |

|

4 |

10000 |

20 |

1.2 |

2 |

4 |

Over Range |

Coarse |

|

5 |

10000 |

25 |

1.5 |

1 |

5 |

Over Range |

Coarse |

|

6 |

12000 |

5 |

0.6 |

3 |

4 |

1.514 |

Smooth |

|

7 |

12000 |

10 |

0.9 |

2 |

5 |

0.839 |

Fine |

|

8 |

12000 |

15 |

1.2 |

1 |

1 |

Over Range |

Coarse |

|

9 |

12000 |

20 |

1.5 |

5 |

2 |

2.804 |

Rough |

|

10 |

12000 |

25 |

0.3 |

4 |

3 |

1.074 |

Smooth |

|

11 |

15000 |

5 |

0.9 |

1 |

2 |

Over Range |

Coarse |

|

12 |

15000 |

10 |

1.2 |

5 |

3 |

5.536 |

Coarse |

|

13 |

15000 |

15 |

1.5 |

4 |

4 |

Over range |

Coarse |

|

14 |

15000 |

20 |

0.3 |

3 |

5 |

0.710 |

Fine |

|

15 |

15000 |

25 |

0.6 |

2 |

1 |

0.711 |

Fine |

|

16 |

20000 |

5 |

1.2 |

4 |

5 |

1.178 |

Smooth |

|

17 |

20000 |

10 |

1.5 |

3 |

1 |

2.131 |

Rough |

|

18 |

20000 |

15 |

0.3 |

2 |

2 |

0.617 |

Fine |

|

19 |

20000 |

20 |

0.6 |

1 |

3 |

Over Range |

Coarse |

|

20 |

20000 |

25 |

0.9 |

5 |

4 |

2.469 |

Rough |

|

21 |

24000 |

5 |

1.5 |

2 |

3 |

0.814 |

Fine |

|

22 |

24000 |

10 |

0.3 |

1 |

4 |

Over range |

Coarse |

|

23 |

24000 |

15 |

0.6 |

5 |

5 |

6.182 |

Coarse |

|

24 |

24000 |

20 |

0.9 |

4 |

1 |

1.420 |

Smooth |

|

25 |

24000 |

25 |

1.2 |

3 |

2 |

Over range |

Coarse |

3.3 Surface Roughness

Surface roughness is a measure of the total spaced surface irregularities [15]. One of the common causes of surface roughness of the machined part is the occurrence of chatter. Chatter also limits the depth of cut and material removal rate of the machining process. Chatter is a self-excited machining vibration that is caused because of relative movement between the cutting tool and the workpiece causing waves on the machined surface. The productivity of machining is often limited by chatter vibration, which is an undesirable phenomenon that occurs in the machining process[16]. One of the most efficient methods to make a chatter-free machine is to make the machine, cutting tool, and workpiece as rigid as possible.

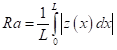

By convention 2D roughness parameters are denoted by capital R, followed by additional subscript characters as in Ra, Rq, Rz, etc. As described in ASME B46.1 [17], Ra is the arithmetic average of the roughness profile within the evaluation length. Ra values are also the most commonly used in industry because of historical reasons. The formula for calculating Ra is given in equation 1.

(1)

(1)

where L is the evaluation length, Z(x) is the profile height function.

The Mitutoyo SJ-210 surface roughness test instrument was employed to measure the surface roughness, Ra following ISO 1997 [18]. The detailed specifications of the test instrument are listed in Table 7.

Table 7: Specification of the Mitutoyo SJ-210

|

Measuring Range / Resolution |

X-axis 16mm / Z-axis 100mm, 0.006mm |

|

Measuring Speed |

0.5mm/s |

|

Measuring Force / Stylus tip |

0.75mN/60º |

|

Cut off Length |

2.5mm |

|

Filter |

Gaussian |

Three measurements were made at different locations for each milling surface. The surface measurements were performed at standard room temperature (22°C). The reported Ra values were the average of three experimental measurements. The corresponding error bars are shown in figure 3.

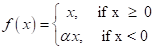

The surface roughness was categorized in four classes as fine (0~ 1mm), smooth (1-2mm), rough (2~4mm), and coarse (>4mm). The class number and range were determined by considering the conditions under which the experimental results are distributed in a balanced manner and the use of workpieces depending on the range of surface roughness in each class. ‘fine’ is mainly used for parts such as bearings where friction in rotating parts must be minimized. ‘smooth’ and ‘rough’ is primarily used in parts such as a high-speed rotation shaft. ‘Coarse’ is usually designated as the roughest surface roughness in parts subjected to force, vibration, and high stress. The stylus used for measuring the surface roughness has an upper limit of Ra=10mm thus, all surface roughness over the range are listed in the fourth class, i.e., coarse.

(2)

(2)